Furniture assembly

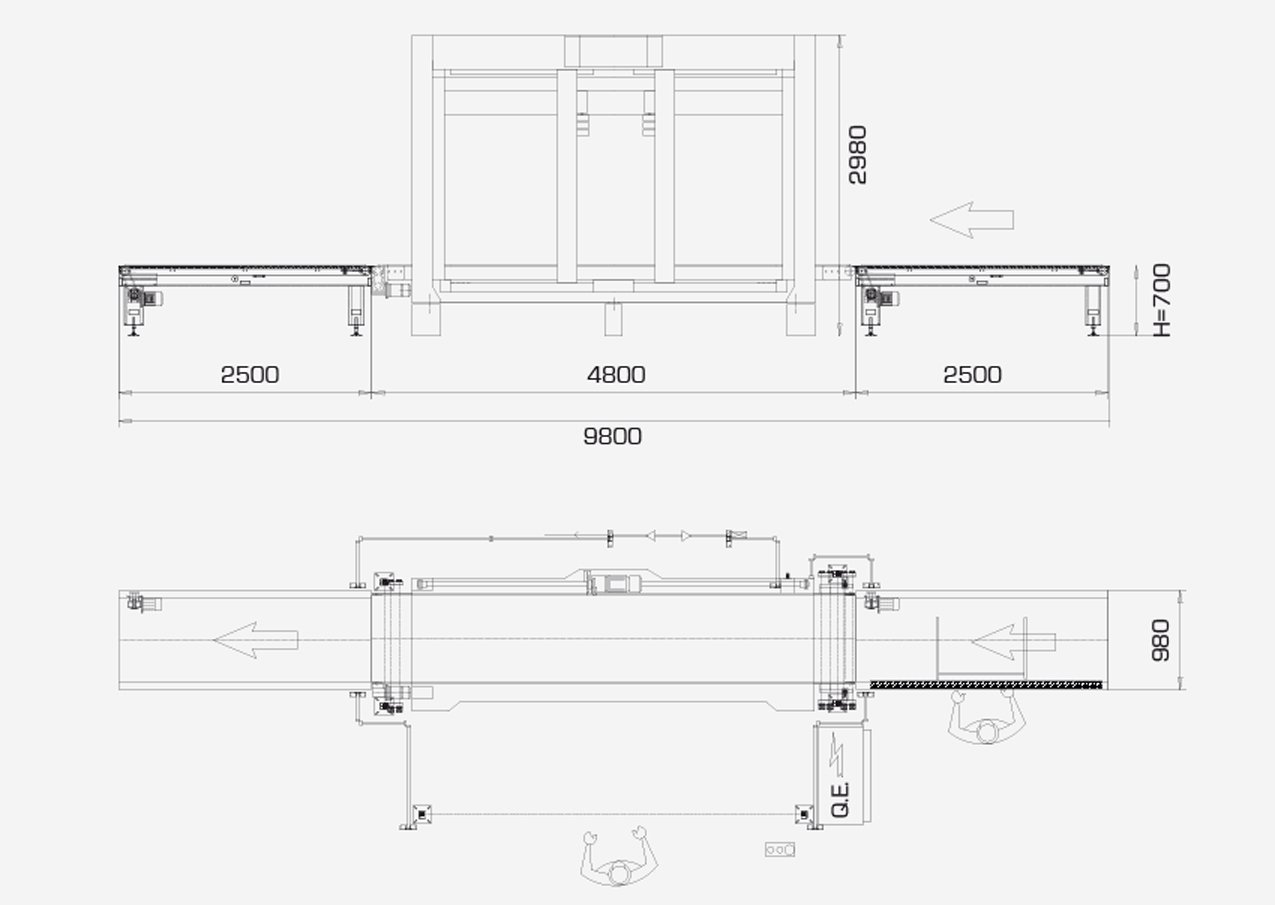

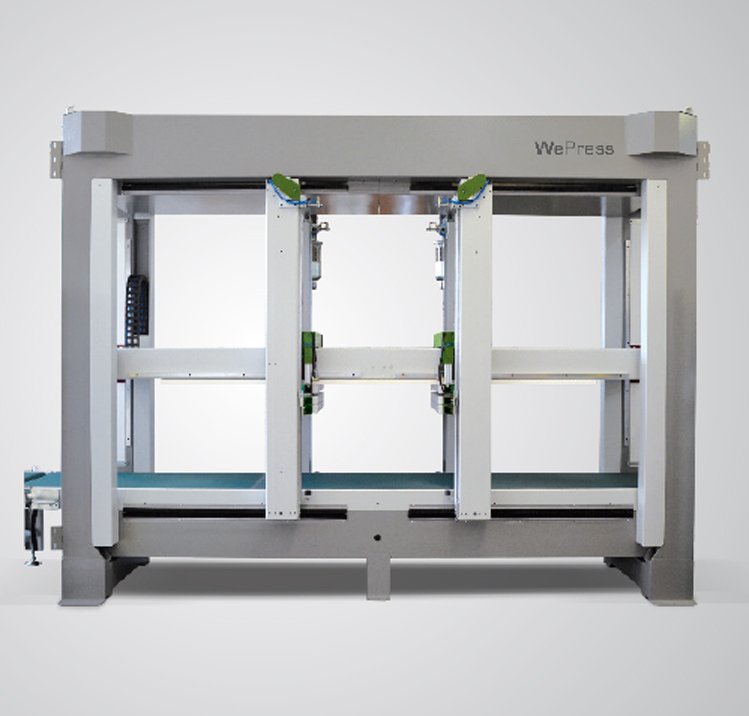

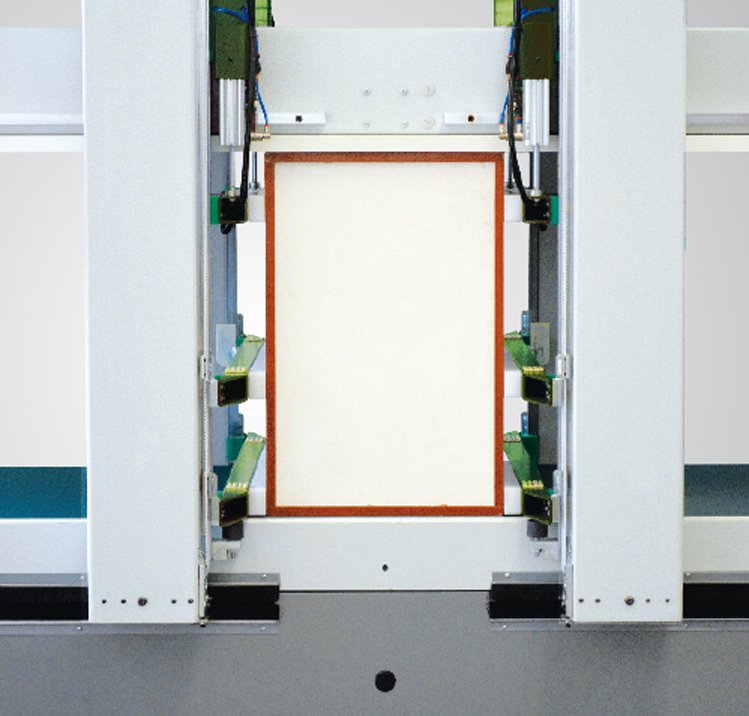

Self-centring press, electro-pneumatic operation, electronic, for furniture, with automatic or manual work cycle. When placing the piece of furniture to be pressed, the machine automatically sets for the size of that piece of furniture, and the operator does not need to intervene. The piece of furniture stops at the central position and the two bars are placed simultaneously at both ends of the piece of furniture for the horizontal pressing. At the same time the horizontal crossbars are automatically positioned, as well as the vertical pressing platform. Both platform and pressing bars are driven by electrical motors. Pressing is pneumatic. The electric panel and the control devices are console-mounted. There are different operating possibilities available, that can be modified at will and recalled via the touch screen found on the electric panel. A PLC controls all machine functions (Movement management, selection of pressing pressure).

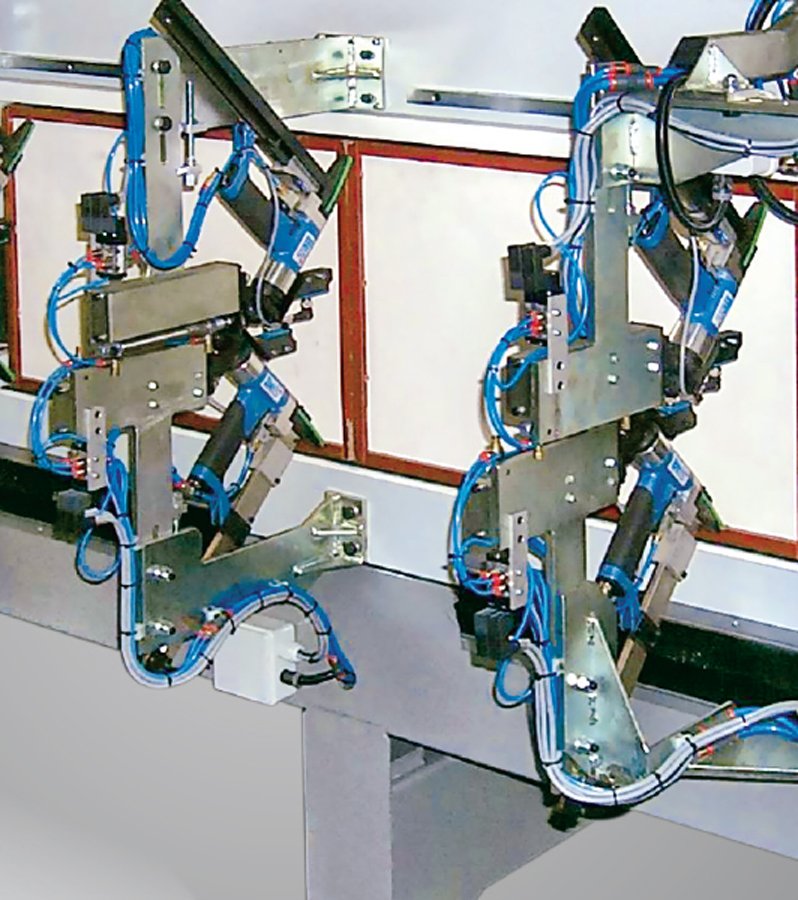

STAPLING OPTIONS Machine prepared for the installation of guns or anthropomorphic robot for the stapling.

WORKING PROCESS

Safety device on the furniture stapling side with safety barriers and metal grid panels to ensure the correct distance from the pressing area.

Handling of the vertical planes and of the horizontal plane with electric motors. Final pneumatic pressing with two dif ferent clamping forces.

Machine with self-centring beams for a greater speed of the production cycle.

Side transversal beams with programmable position and top crossbar with pneumatic system for the pressing of furniture with an overhanging top.

Sensors system for the self-sizing of the machine.

Easy and intuitive operator’s interface.

| Performance | up to 2 furnitures/min. |

| Max useful dimensions | 2500 L/ 820 W/ 1200 H mm |

| Min. useful dimensions | 250 L/ 300 W/ 250 H mm |

| Overall dimension | 4800 L/ 1340 W/ 2540 H mm |